Fowler

Associates Helps Solve

Electrostatic

Problems with RFID Label Manufacturing

Electrostatic

Problems with RFID Label Manufacturing

"If

I were to design a product which would have the most electrostatic problems,

I would design today's RFID labels. "

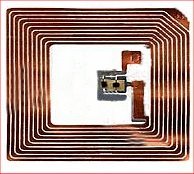

Think

of it: A high speed insulative web with isolated conductive antennae

onto which, in line, a sensitive integrated circuit will be placed.

That spells trouble. Industries such as textiles, plastics and labels

now have to become electronic manufacturing companies. Not only do they

have to be as ESD safe as the major IC and circuit manufacturers, their

product disallows most ESD safe practices such as removal of all static

chargers in the process. Their product is a static charger by the process.

Think

of it: A high speed insulative web with isolated conductive antennae

onto which, in line, a sensitive integrated circuit will be placed.

That spells trouble. Industries such as textiles, plastics and labels

now have to become electronic manufacturing companies. Not only do they

have to be as ESD safe as the major IC and circuit manufacturers, their

product disallows most ESD safe practices such as removal of all static

chargers in the process. Their product is a static charger by the process.

Steve

Fowler has worked successfully with industries to solve their problems

as they begin and expand their RFID manufacturing.

The

first RFID tags were much less sensitive than today and certainly than

tomorrow. As the sensitivities increase and as the yields of companies

fall, the more the need for solutions to the static problems with RFID

manufacturing.

Our

solutions involve:

1.

Assistance in the design of the machines for RFID labels to reduce static

issues

2. Assistance with the design of the labels and antennae to reduce static

issues

3. On site support and review of the process to optimize out static

problems

4. Training of personnel to keep static issues out of the process

5. Follow-up reviews as the process changes and speeds up.

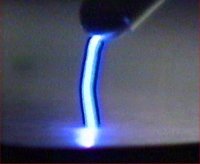

With

the prudent application of good electrostatic design principles as well

as the appropriate use of both passive and active ionization techniques,

the RFID label process can be profitable.

With

the prudent application of good electrostatic design principles as well

as the appropriate use of both passive and active ionization techniques,

the RFID label process can be profitable.

We

guide the manufacturer through the muddy waters of electrostatic problems.

Electrostatics

may be the oldest electrical science. However, it is still one of the

least understood. Let Fowler Associates assist you in your understanding.

Some related Web Articles:

http://www.simco-static.com/data/RFIDTagsandLabels.shtml

http://www.rfidjournal.com/article/articleview/1980/1/82/